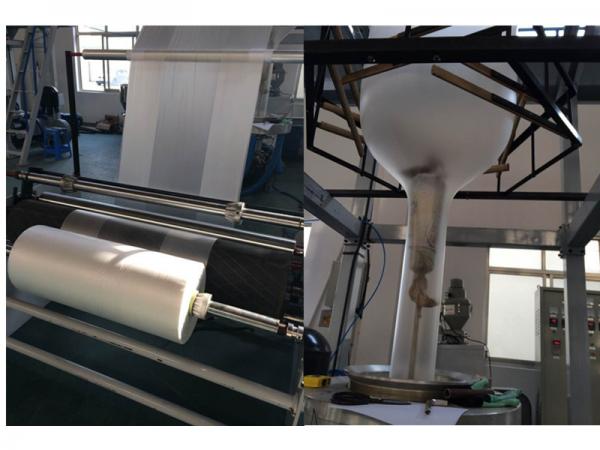

Film blowing machine operation

In order to regulate the operation, ensure the equipment and personal safety, product quality, according to the requirements of the operating equipment.

Preparation:

2 people were required to wear work clothes, shoes and hats etc..

1) Check the scene

2) Inspection equipment is free of foreign matter, especially at the corners.

3) Check the equipment repair and maintenance free unfinished.

4) Check the heater wiring intact right.

5) To check all the switch is in the off state, the potentiometer in zero state.

6) Turn on the main switch, Make sure there is no abnormalsituation, check all the equipment running status, no abnormal shut-down.

7) Check the water circulation system (including cooling tower).

8) Check the cooling system.

9) Check the loading system and hopper, Material should be dryed in advance if need.

10)Fill in enough water into water tank as requirement.

11) The main motor speed control button (inverter) is in zero, forbid to press the start button.

12) The production environment, equipment, material, water in accordance with the process and health requirements.

13) Raw materials will be transported gradually from the control area to clean area.

1) Set the temperature according to the requirement of process.

2) If the die head is large, can close the other district heating, die preheating first.

3) When the die is heated to a certain temperature and time, according to the process requirements to turn on the barrel heating.

4) Check the heating current or temperature if any abnormal situation.

5) After the inspection is completed, turn on the water circulating pump (host tank pump) and the main pump or cooling tower, and switch on the throat cooling water.

6) When the temperature reaches the set value, need (constant) holding 0.5-1.5h (according to the equipment width).

7) According to the process requirements, start chiller in suitable time.

1) The screw can rotated by manual, turn on the machine.

2) Check the belt tightness, meet the requirements.

3) A screen or perforated plate (die connection or T die) should be cleaned up.

4) If the new die must be fastening and connecting screws, screw shall be in accordance with the requirements of strength grade.

5) Check the screw is rotated right (counterclockwise).

6) The inspection is completed, start the host

Note: in front of the die no person allowed, avoid to hot air or hot material burns out die.

7) If the barrel without the material , the screw speed should be controlled at 3~10rpm, for material or discharge the compressed air from mould, we can speed up according to process requirements, speed up the process, pay attention to observe the various process parameters, such as temperature, pressure, current.

8) If there is abnormal sound, pressure changes, abnormal or beyond the current requirements, should immediately stop and check to report.

9) At the low speed condition, get film discharging, adjust the width, thickness and thickness uniformity, then speed up, make the product width, thickness and uniformity, mechanical parameters (film, stretch) to meet the requirements.

10) Cleaning die, must use copper shovel or wood and other soft tool, rigorous use hard tool, so as not to hurt the lip and face of runner.

1) Familiar with the equipment, to concentrate on operating.

2) Electrical maintenance, there must be other person with supervision, and placed warning signs in the relevant position.

3) The maintenance of equipment, the relevant switch is off, and placed warning signs.

4) Prohibits staff or objects near the high temperature parts, especially the bare heater and its terminal.

5) Volatile flammable materials according to the relevant requirements.

6) Staff will use the fire extinguisher, and clearly understand the fire knowledge, kinds of fire extinguisher and how to use, escape knowledge, workshop should be with obivious escape signs.

7) For climbing the operation, must have the safety protection measures.

8) Production personnel must have production and operation, product requirements, safety knowledge training.