Project Description

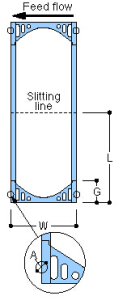

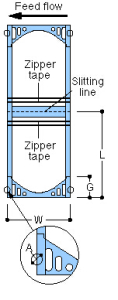

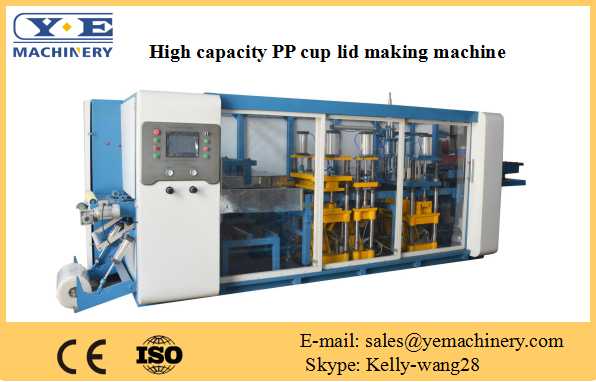

It is an ideal Bag making equipment for producing three-side sealing bags, stand up pouch, zipper bag, stand up pouch with zipper, with 3 servo motor. Material: Laminated Film As; LDPE, CPP, MCPP, AL, NYLON, PP etc.

Featrues:

1. Whole machine controlled by central PLC control system with touch screen. More stable performance, easy for operation and maintenance. Chinese and English interface language can be changed easily.

2. Constant auto-tension control for unwinding, EPC edge alignment, AC inverter constant speed auto material feeding.

3. Imported double servo-motor material traction control system

4. Main motor for up-down sealing and pressing equipped with inverter.

5. PID for sealing bar temperature adjustment, no touch auto control, centralized setting in man-machine interface.

6. Equipped with Pneumatic multi-function auto punching device, trim cutting and auto rewinding and static eliminator

7. Temperature adjustment range: 0~300℃

8. Counter: quantity, batch accumulation, pre-set available.

9. Operation Method: by length fixation control and/or by photocell tracking control.

10. Punching device: working rhythm can pre-set as continuous, interval or stop, punching time can be pre-set.

11. Material Skip Feeding: 1-6 times available.

12. Batch Conveying Function available, the quantity of batch can be pre-set.

Main Parameters:

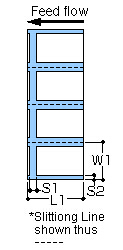

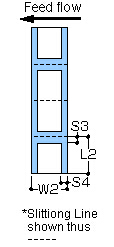

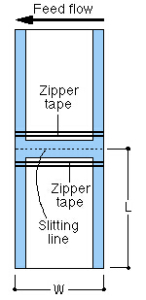

| 1 | Produced Bag Type | 3-side sealing, stand up pouch, zipper bag, stand-up zipper pouch |

| 2 | Unwinder Max.Size | Width Max=1250mm, Diameter Max=600mm |

| 3 | Material Type | Laminated Film As; LDPE, CPP, MCPP, AL, NYLON, PP etc. |

| 4 | Bag Size | Max. Length 400mm ( more than 400mm, multiple Infeed 6 times )Max.Width 600mm |

| 5 | Machine Speed | 150t/min |

| 6 | Unwind Line Speed | ≤ 40 m/min |

| 7 | Main Motor | 3.5 KW (Taiwan, with inverter Japan Yaskawa) |

| 8 | Infeed Drive & Motor | Front Infeed 1kw AC Servo (MITSUBISHI) Middle Infeed 1.5kw Ac Servo(MITSUBISHI) Back Infeed 1kw AC Servo (MITSUBISHI ) |

| 9 | Model of Control System: | Panasonic PLC (Made in Japan) high speed bag making control system. |

| 10 | Temperature Control | PC Control 24 set. ± 2℃ |

| 11 | Temperature control range: | environmental temperature to 300℃ |

| 12 | Horizontal Heater | 3 units, heating up and down, 640mm |

| 13 | Horizontal Cooling | 2 units, cooling, 640mm |

| 14 | Vertical Heater | 5 units, 800mm |

| 15 | Vertical Cooling | 5 units, 400mm |

| 16 | Zipper heating | 2 units, 640mm |

| 17 | Zipper cooling | 2 units, 330mm |

Bag making machine for stand up pouch and zipper bag

It is an ideal Bag making equipment for producing three-side sealing bags, stand up pouch, zipper bag, stand up pouch with zipper, with 3 servo motor. Material: Laminated Film As; LDPE, CPP, MCPP, AL, NYLON, PP etc.

Recent Works

- Cotton Buds Swabs Making Packing Machineadmin2017-02-24T10:52:40+00:00

Cotton Buds Swabs Making Packing Machine