Project Description

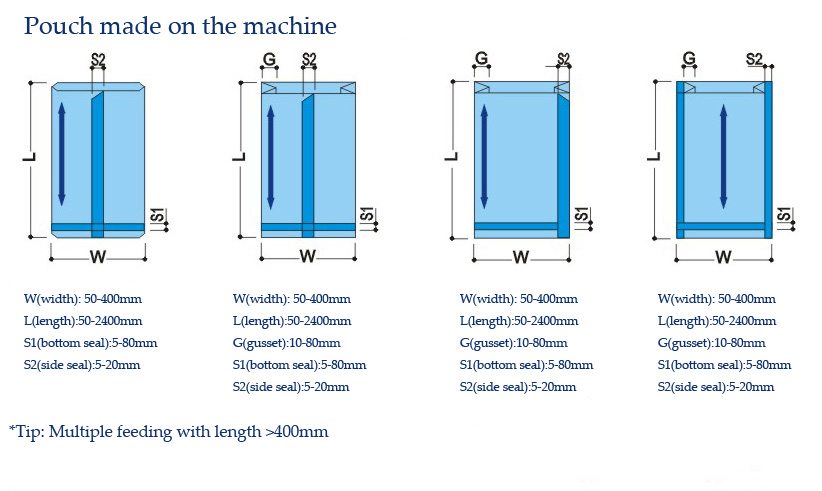

It is an ideal Bag making equipment for producing central sealing, four-side sealing bags, side sealing bag, with 2 servo motor. Material: Laminated Film As; LDPE, CPP, MCPP, AL, NYLON, PP etc.

Featrues:

1. Whole machine controlled by central PLC control system with touch screen. More stable performance, easy for operation and maintenance. Chinese and English interface language can be changed easily.

2. Constant auto-tension control for unwinding, EPC edge alignment, AC inverter constant speed auto material feeding.

3. Imported double servo-motor material traction control system.

4. Main motor for up-down sealing and pressing equipped with inverter.

5. PID for sealing bar temperature adjustment, no touch auto control, centralized setting in man-machine interface.

6. Equipped with Pneumatic multi-function auto punching device, trim cutting and auto rewinding and static eliminator.

7. Temperature adjustment range: 0~300℃.

8. Counter: quantity, batch accumulation, pre-set available.

9. Operation Method: by length fixation control and/or by photocell tracking control. 10. Punching device: working rhythm can pre-set as continuous, interval or stop, punching time can be pre-set.

11. Material Skip Feeding: 1-6 times available.

12. Batch Conveying Function available, the quantity of batch can be pre-set.

Main Parameters:

| Type | ZD-400CS | ZD-500CS | ZD-600CS |

| Max. Diameter Of Roll Material | 600mm | 600mm | 600mm |

| Max. Width Of Roll Material | 1050mm | 1050mm | 1250mm |

| Max.Capacity | 150pieces/min | 150pieces/min | 150pieces/min |

| Max.Mechanical Speed | about.35m/min | about.35m/min | about 35m/min |

| Total Power | 25Kw | 30Kw | 35Kw |

| Weight | 4500kg | 5000kg | 5500kg |

| Overall Dimension (L*W*H) | 10000*1500*1870mm | 10000*1600*1870mm | 10000*1700*1870mm |

Recent Works

- Cotton Buds Swabs Making Packing Machineadmin2017-02-24T10:52:40+00:00

Cotton Buds Swabs Making Packing Machine